DIY LED Shoe Closet

We have a ton of shoes, and the little shoe rack shown below was not cutting it. I had been harassing Chris about wanting to do something cool in the front entrance closet, but he wasn't into it until I mentioned custom lighting. Yay!

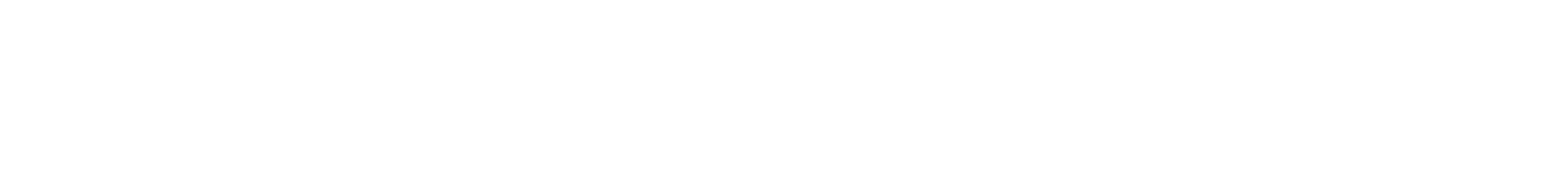

We decided to use half of the closet for shoes and the other half for coats. Chris started by making a scale diagram in Illustrator. Initially we were going to have slide out drawers. We figured it would be way too much work though, so we opted for the design on the right with just shelves. After carefully measuring and designing, Chris got to work on construction.

He started by creating a recessed base for the cabinets out of 2x4, just as we've done with other built in units. He then built two separate boxes from white melamine - one on the left for the shoes which would have under lit shelves, and the other on the right for coats which would have lighting along the edges.

For the shelves, he used a table saw to create strips that matched the depth of the cabinet. He also cut thinner strips of melamine the same width of the shelves that would be used for the overhangs. The shelves and overhang strips were screwed together from the bottom to make an "L" shape. Screw holes were then covered with iron on white edge banding. The overhangs not only make the shelf faces look chunkier, but they also stiffen the shelves and hide LED strips.

Note the "L" shape of the shelves which stiffen the design and provide a recess to hide LED strips.

Once the boxes were finished and shelves screwed in place, holes were drilled in the cabinet walls just behind the faces of each shelf. These were just big enough to feed wires through to supply the LED strips. Chris also routed channels in the sides of the cabinets to run low voltage wires.

Four screws were used to affix each shelf per side. Holes were also drilled to feed wires to each shelf, located just behind the overhanging face plates. A combination square was used to mark the distance from the front of the shelf to these holes.

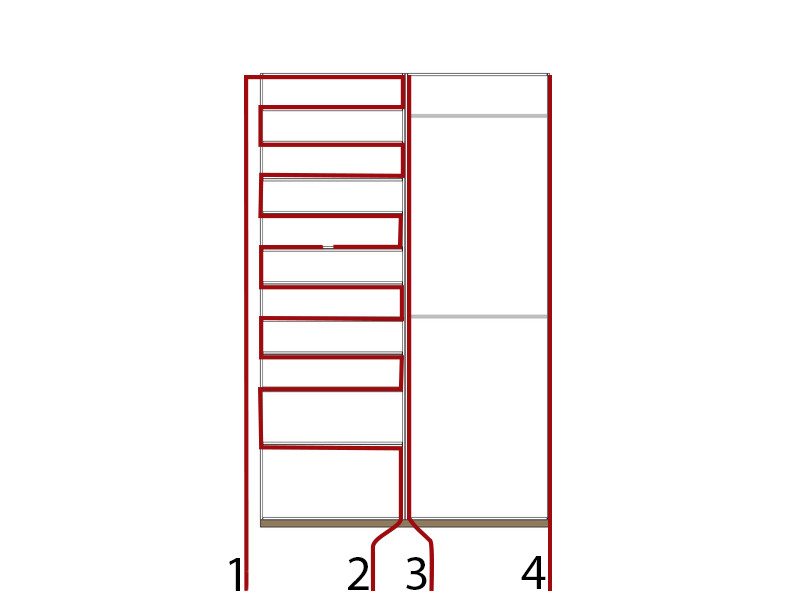

If you would like to know how to wire LEDs, see this post for the basics. For the shoe shelf side of the closet, Chris created two parallel branches, one supplying the top half of the shelves and one supplying the bottom half. All the shelves on each parallel branch were wired end-to-end in a daisy chain fashion, zig-zagging from one side of the shelving unit to the other. Picture power entering from one side of the shelving unit, traveling across the shelf and supplying LEDs, then jumping to the next shelf level, traveling back the other way supplying LEDs, then jumping to the next level, etc. The reason Chris didn't wire all shelves in one big long string (i.e. in a single long daisy chain) was to minimize voltage drop and hence brightness drop between the first and last LEDs. Since there were an odd number of shelves, the middle shelf is supplied by the ends of both the top and bottom circuits. The coat rack side of the closet was far simpler and wired as just two straight parallel branches, one on each side of the cabinet. See the wiring diagram below.

Branches 1 and 2 supply the shoe shelf side of the closet and are supplied by their own LED driver. Branches 3 and 4 supply the coat side and are on their own driver. Both drivers are plugged into an Inseton LampLinc unit for automation/control.

The long channel of wire brings power to the top half of the shelves. Note the channels cut to connect the shelves in a zig-zagging fashion, traveling from shelf to shelf like the path a sewing needle would take.

Chris added some packing tape over the wires to keep them in their grooves. This would not be seen so it didn't have to have a finished look.

Once the LED strips were all in place and hooked up, we tested the lighting before installing the cabinet. Always test!

View from the back of the cabinet before installation.

Crimp on quick connectors were used at every connection, allowing for solderless swapping of LED strips in case one needs to be replaced. Note that once everything was confirmed to be working properly, these unsightly wires and connectors were taped to the under surface of each shelf with white duct tape which blends in with the shelving unit.

Before installing the cabinets in the closet, thin sheets of white melamine were cut to size and used to cover the backs of the cabinets. We then placed the first cabinet in the closet and screwed it in place.

We then installed the other cabinet. You can see the wires are now concealed.

Thick chrome rods were installed for the coats.

The two bifold closet doors were swapped out for two standard flat-front doors. These were a bit too big for the opening, so Chris planed them down to fit properly. Levers matching the rest of the house were installed and magnetic catches were used for a closing mechanism.

The final touch was installing an Insteon door contact, with the sensor on one door and magnet on the other. This way whenever either door is opened, the sensor trips which Chris has programmed to automatically turn on the closet LEDs. They turn off automatically when both doors are shut. If you're curious about the home automation bit, see this post.